Download Analyst Report

How to Optimize Manufacturing Finance with FP&A Software

Learn how to optimize costs, streamline compliance, and boost profits with strategic manufacturing insights.

June 12, 2025In most manufacturing companies, financial software has changed the way finance teams track, manage, and optimize profitability. The evolution from basic or manual accounting systems to sophisticated, intelligent software empowers the CFO's office to perform essential finance tasks efficiently and accurately.

Modern ERP systems store valuable data for manufacturing finance teams. And bringing it into FP&A software helps data flow seamlessly across departments, eliminating silos and enhancing visibility at every level of your organization.

These advancements couldn't have come at a better time. As supply chains grow more volatile, demand fluctuates, and material costs continue to rise, optimizing your financial processes with the right tools becomes essential. Manufacturing sector CFOs need deep data delivered through intuitive tools to stay ahead of these challenges.

Intelligent financial performance management software is essential for addressing manufacturing's most pressing challenges while driving strategic initiatives.

The strategic value of manufacturing finance

Keeping financial planning aligned with operations is key to growth in the manufacturing industry. Even in stable market conditions, profitability remains under constant pressure, which is why the impact of material costs, inefficient manufacturing processes, and fluctuating demand cannot be overstated. Properly overseeing these factors and understanding their place in your strategy depends on relevant, timely financial data.

Too many finance teams are still overburdened with manual data entry and legacy tools. A fully integrated financial platform centralizes data from multiple sources so you can access key financial and non-financial data and create performance reports that give leaders real-time visibility on production costs, revenues, and other aspects of finance. Processes become more streamlined and finance teams can continue to add value to strategic decisions.

Both service companies and manufacturing companies need stronger, tailored solutions for making financial data more available.

Key financial challenges in modern manufacturing

Cost allocation and capital expenditures

In manufacturing, expenses and revenue are spread out over multiple product lines, machinery, and departments. That can make getting a clear picture of profitability difficult, especially when costs and profits for specific products, SKUs, and customers can be spread across multiple siloed systems.

Without SKU-level insight, manufacturers might invest in equipment, capacity, or automation to support products that appear to be profitable in aggregate. But when you analyze them by SKU, it becomes obvious that they are impacting your margins. This often leads to inefficiencies in capital expenditure.

Cash flow fluctuations and seasonality

Cash flow feeds your manufacturing company, but keeping this flow stable is increasingly difficult. Demand can be volatile, especially for seasonal products, meaning every finance leader in manufacturing has to carefully balance keeping production high enough to meet demand without creating a surplus that takes up storage space and creates other costs. Add in supply chain issues, and you have a perfect recipe for skyrocketing costs and unreliable cash flows. Even worse, all the data you need to optimize your cash flow is found across too many systems, like multiple ERPs, MES, and spreadsheets.

FP&A software allows manufacturing leaders to monitor cash flows across products without manually analyzing data, permitting on-the-fly adjustments to strategy to maintain sustainable growth across the entire organization.

Leveraging FP&A software for operational efficiency

Automation and workflow efficiencies

In most manufacturing companies, financial workflows are burdened with manual effort and the risk of human error due to over-reliance on spreadsheets. Financial performance platforms that are designed for FP&A for manufacturing businesses automate these workflows and centralize data from multiple sources, allowing leaders to get the information they need to make better decisions. Prophix customer Silafrica Packaging, for example, accelerated their month-end by 67%, leading to $37,800 in annual labor savings.

Analytics and reporting advancements

Automation is just one piece of the puzzle. FP&A software also delivers essential financial data in dashboards that can be used to get a bird’s-eye view of that data or drill down into specific variables. AI-powered analytics can generate commentary and provide summaries of your data, so you have a clear picture of your financial performance and can act when needed.

FP&A software gives the Office of the CFO a single, integrated solution for analysis and financial reporting, allowing for more data-driven decisions.

Practical techniques for cost optimization and investment

Working capital and inventory management

Optimizing working capital while maintaining operational efficiency requires a sophisticated approach. Data-driven inventory management systems allow manufacturers to reduce carrying costs while ensuring they have enough necessary materials on hand to support their operations. Strategic cost accounting aligned with supply chain finance solutions can significantly lower associated operational costs for manufacturers, from over-ordering materials to incorrectly prioritizing less profitable products.

Modern manufacturer financing options have evolved to include inventory-specific financing strategies in an effort to access trapped working capital. These financing strategies are put in place to, for example, bridge seasonal gaps in cash flow, fund large orders or purchase new inventory, and can help avoid delays in capital spending due to working capital constraints. With FP&A software, you can access real-time data and insights to know when the best time is to leverage financing options – and how.

Long-term investment planning

Beyond the day-to-day of running manufacturing operations, finance leaders have to plan for long-term investments in new machinery, facility expansion, or even acquiring new real estate. While these investments are essential for long-term success, they also introduce substantial risk if not properly evaluated against future revenue projections and market conditions.

Financial performance platforms with robust data analytics can better equip these leaders to make these decisions. Prophix’s forecasting capabilities allow leaders to model various scenarios before committing capital, accounting for variables like equipment depreciation, maintenance costs, and productivity improvements. This forward-looking investment strategy, grounded in data rather than intuition, keeps cash flow stable without stifling growth.

Ensuring compliance and minimizing risk

Regulatory requirements for manufacturing CFOs

CFOs and other finance leaders face complex regulatory requirements, including industry-specific standards, environmental regulations, tax codes, and financial reporting requirements. Compliance is a constantly evolving mandate, requiring the systematic integration of compliance in everyday operations.

Internal controls must be robust enough to meet these requirements without stifling daily operations. Modern financial performance platforms automate documentation, standardize reporting formats, automate account reconciliation, send notifications if there are discrepancies, and create comprehensive audit trails, facilitating compliance.

Compliance isn’t just about avoiding penalties; it’s about protecting brand reputation and maintaining stakeholder trust.

Risk assessment and scenario planning

Traditional risk management approaches aren’t enough. Forward-thinking CFOs use rigorous scenario planning to quantify the potential impacts of all-too-common variables like supply chain disruptions, material cost fluctuations, labor shortages, and market shifts.

FP&A software allows finance leaders in manufacturing to build dynamic models that test multiple variables simultaneously to uncover potential vulnerabilities. From the reports and dashboards in these tools, any finance team can plan a response to even the most complex risk scenario.

Real-time risk monitoring capabilities further enhance a manufacturer’s internal controls to identify early warning signals and implement preemptive measures. Transitioning from annual risk reviews to continuous assessments allows leaders to maintain operational continuity while supporting strategic initiatives for growth.

Aligning finance and production for strategic growth

Integrating departmental goals

Seamless collaboration between production and finance teams is essential to your success. When operational managers understand financial constraints and CFOs grasp production realities, manufacturing companies set more achievable targets and build stronger forecasts. A unified data system that gives both teams access to the same real-time information creates a shared foundation for planning that transcends departmental barriers.

Outcome-driven KPIs and expanded profitability

Your strategy depends on metrics that connect production activities to financial outcomes. Outcome-driven KPIs like contribution margin per machine hour and quality-adjusted productivity reveal this relationship in ways that allow leaders to make stronger, data-driven decisions. This approach increases stakeholder confidence by demonstrating clear links between operational improvements and financial performance.

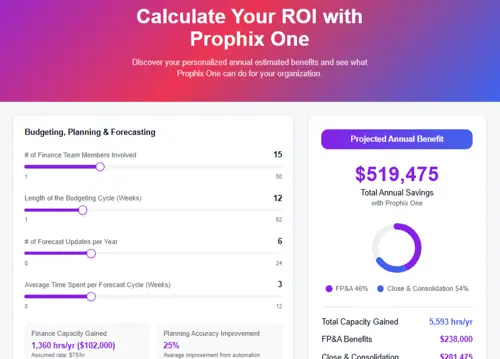

Drive better growth in manufacturing with stronger financials

FP&A software gives manufacturing leaders a single, unified platform for processing, analyzing, and reporting on financial data throughout the organization. Solutions like Prophix One FP&A Plus give CFOs what they need to build automated workflows, streamline repetitive tasks, and improve data accuracy—all contributors to driving strategic growth.

Want to see what Prophix One can do for manufacturing?